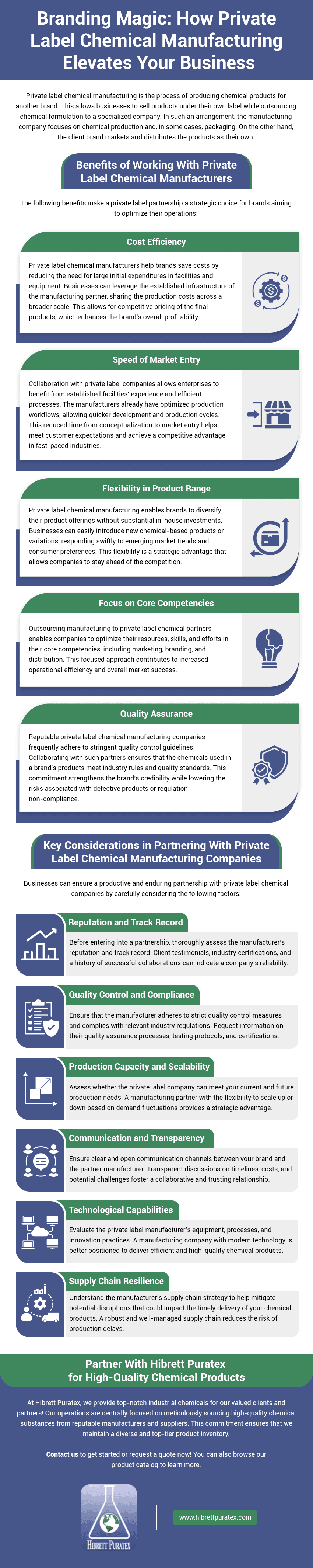

Private label chemical manufacturing is the process of producing chemical products for another brand. This allows businesses to sell products under their own label while outsourcing chemical formulation to a specialized company. In such an arrangement, the manufacturing company focuses on chemical production and, in some cases, packaging. On the other hand, the client brand markets and distributes the products as their own.

This article will examine the benefits of private label chemical manufacturing and the key considerations before entering a partnership.

Benefits of Working With Private Label Chemical Manufacturers

The following benefits make a private label partnership a strategic choice for brands aiming to optimize their operations:

Cost Efficiency

Private label chemical manufacturers help brands save costs by reducing the need for large initial expenditures in facilities and equipment. Businesses can leverage the established infrastructure of the manufacturing partner, sharing the production costs across a broader scale. This allows for competitive pricing of the final products, which enhances the brand’s overall profitability.

Speed of Market Entry

Collaboration with private label companies allows enterprises to benefit from established facilities’ experience and efficient processes. The manufacturers already have optimized production workflows, allowing quicker development and production cycles. This reduced time from conceptualization to market entry helps meet customer expectations and achieve a competitive advantage in fast-paced industries.

Flexibility in Product Range

Private label chemical manufacturing enables brands to diversify their product offerings without substantial in-house investments. Businesses can easily introduce new chemical-based products or variations, responding swiftly to emerging market trends and consumer preferences. This flexibility is a strategic advantage that allows companies to stay ahead of the competition.

Focus on Core Competencies

Outsourcing manufacturing to private label chemical partners enables companies to optimize their resources, skills, and efforts in their core competencies, including marketing, branding, and distribution. This focused approach contributes to increased operational efficiency and overall market success.

Quality Assurance

Reputable private label chemical manufacturing companies frequently adhere to stringent quality control guidelines. Collaborating with such partners ensures that the chemicals used in a brand’s products meet industry rules and quality standards. This commitment strengthens the brand’s credibility while lowering the risks associated with defective products or regulation non-compliance.

Key Considerations in Partnering With Private Label Chemical Manufacturing Companies

Businesses can ensure a productive and enduring partnership with private label chemical companies by carefully considering the following factors:

- Reputation and track record: Before entering into a partnership, thoroughly assess the manufacturer’s reputation and track record. Client testimonials, industry certifications, and a history of successful collaborations can indicate a company’s reliability.

- Quality control and compliance: Ensure that the manufacturer adheres to strict quality control measures and complies with relevant industry regulations. Request information on their quality assurance processes, testing protocols, and certifications.

- Production capacity and scalability: Assess whether the private label company can meet your current and future production needs. A manufacturing partner with the flexibility to scale up or down based on demand fluctuations provides a strategic advantage.

- Communication and transparency: Ensure clear and open communication channels between your brand and the partner manufacturer. Transparent discussions on timelines, costs, and potential challenges foster a collaborative and trusting relationship.

- Technological capabilities: Evaluate the private label manufacturer’s equipment, processes, and innovation practices. A manufacturing company with modern technology is better positioned to deliver efficient and high-quality chemical products.

- Supply chain resilience: Understand the manufacturer’s supply chain strategy to help mitigate potential disruptions that could impact the timely delivery of your chemical products. A robust and well-managed supply chain reduces the risk of production delays.

Partner With Hibrett Puratex for High-Quality Chemical Products

At Hibrett Puratex, we provide top-notch industrial chemicals for our valued clients and partners! Our operations are centrally focused on meticulously sourcing high-quality chemical substances from reputable manufacturers and suppliers. This commitment ensures that we maintain a diverse and top-tier product inventory.

Contact us to get started or request a quote now! You can also browse our product catalog to learn more.