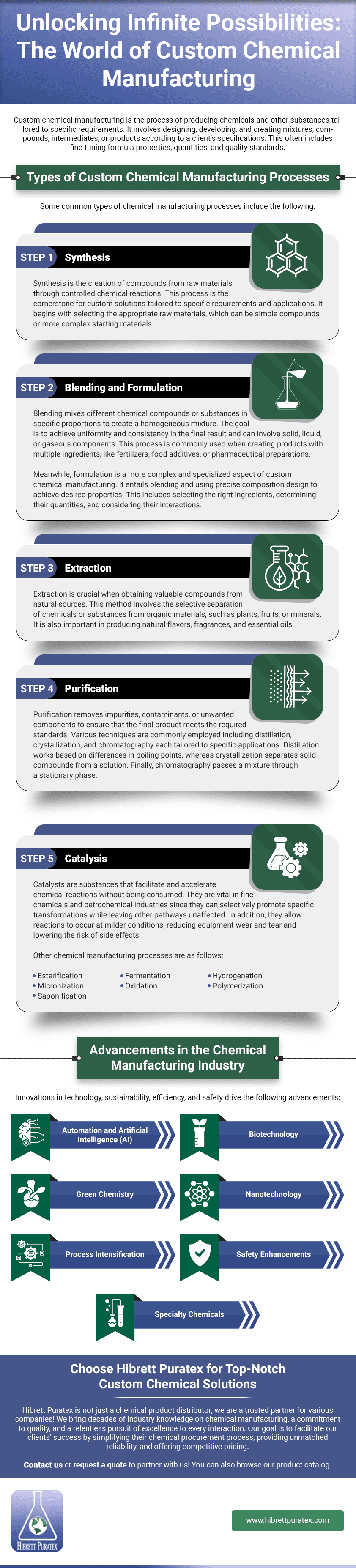

Custom chemical manufacturing is the process of producing chemicals and other substances tailored to specific requirements. It involves designing, developing, and creating mixtures, compounds, intermediates, or products according to a client’s specifications. This often includes fine-tuning formula properties, quantities, and quality standards.

This article will delve into the intricacies of tailored chemical solutions, covering the manufacturing processes and recent advancements in this industry.

Types of Custom Chemical Manufacturing Processes

Some common types of chemical manufacturing processes include the following:

Synthesis

Synthesis is the creation of compounds from raw materials through controlled chemical reactions. This process is the cornerstone for custom solutions tailored to specific requirements and applications. It begins with selecting the appropriate raw materials, which can be simple compounds or more complex starting materials.

Blending and Formulation

Blending mixes different chemical compounds or substances in specific proportions to create a homogeneous mixture. The goal is to achieve uniformity and consistency in the final result and can involve solid, liquid, or gaseous components. This process is commonly used when creating products with multiple ingredients, like fertilizers, food additives, or pharmaceutical preparations.

Meanwhile, formulation is a more complex and specialized aspect of custom chemical manufacturing. It entails blending and using precise composition design to achieve desired properties. This includes selecting the right ingredients, determining their quantities, and considering their interactions.

Extraction

Extraction is crucial when obtaining valuable compounds from natural sources. This method involves the selective separation of chemicals or substances from organic materials, such as plants, fruits, or minerals. It is also important in producing natural flavors, fragrances, and essential oils.

Purification

Purification removes impurities, contaminants, or unwanted components to ensure that the final product meets the required standards. Various techniques are commonly employed including distillation, crystallization, and chromatography each tailored to specific applications. Distillation works based on differences in boiling points, whereas crystallization separates solid compounds from a solution. Finally, chromatography passes a mixture through a stationary phase.

Catalysis

Catalysts are substances that facilitate and accelerate chemical reactions without being consumed. They are vital in fine chemicals and petrochemical industries since they can selectively promote specific transformations while leaving other pathways unaffected. In addition, they allow reactions to occur at milder conditions, reducing equipment wear and tear and lowering the risk of side effects.

Other chemical manufacturing processes are as follows:

- Esterification

- Fermentation

- Hydrogenation

- Micronization

- Oxidation

- Polymerization

- Saponification

Advancements in the Chemical Manufacturing Industry

Innovations in technology, sustainability, efficiency, and safety drive the following advancements:

- Automation and artificial intelligence (AI): Automation and AI are increasingly used to optimize chemical processes, monitor production, and enhance safety.

- Biotechnology: Innovations in biotechnology have led to the development of bio-based chemicals and renewable feedstocks, reducing reliance on fossil fuels.

- Green chemistry: Contributing to sustainable chemical manufacturing, green chemistry focuses on developing processes that reduce or eliminate the use and generation of hazardous substances.

- Nanotechnology: Nanomaterials and nanoparticles have applications in various industries, including catalysis, drug delivery, and materials science.

- Process intensification: Techniques like continuous flow processes, microreactors, and miniaturization have improved efficiency and reduced waste.

- Safety enhancements: Improved safety measures including advanced process control, risk assessment, and safety training have reduced accidents and incidents in chemical plants.

- Specialty chemicals: Developing specialty blends with specific properties and applications has expanded the market for customized chemical products.

Choose Hibrett Puratex for Top-Notch Custom Chemical Solutions

Hibrett Puratex is not just a chemical product distributor; we are a trusted partner for various companies! We bring decades of industry knowledge on chemical manufacturing, a commitment to quality, and a relentless pursuit of excellence to every interaction. Our goal is to facilitate our clients’ success by simplifying their chemical procurement process, providing unmatched reliability, and offering competitive pricing.

Contact us or request a quote to partner with us! You can also browse our product catalog.